The Power of CNC Lathe Machines in Modern Manufacturing

In today’s fast-paced manufacturing world, precision and efficiency are non-negotiable. That’s where CNC (Computer Numerical Control) lathe machines come in, revolutionizing how parts are produced across various industries. Whether you’re working in automotive, aerospace, or electronics, a CNC lathe offers unmatched accuracy, speed, and versatility. But what exactly makes these machines so valuable, and why are they a staple in modern production processes?

What is a CNC Lathe Machine?

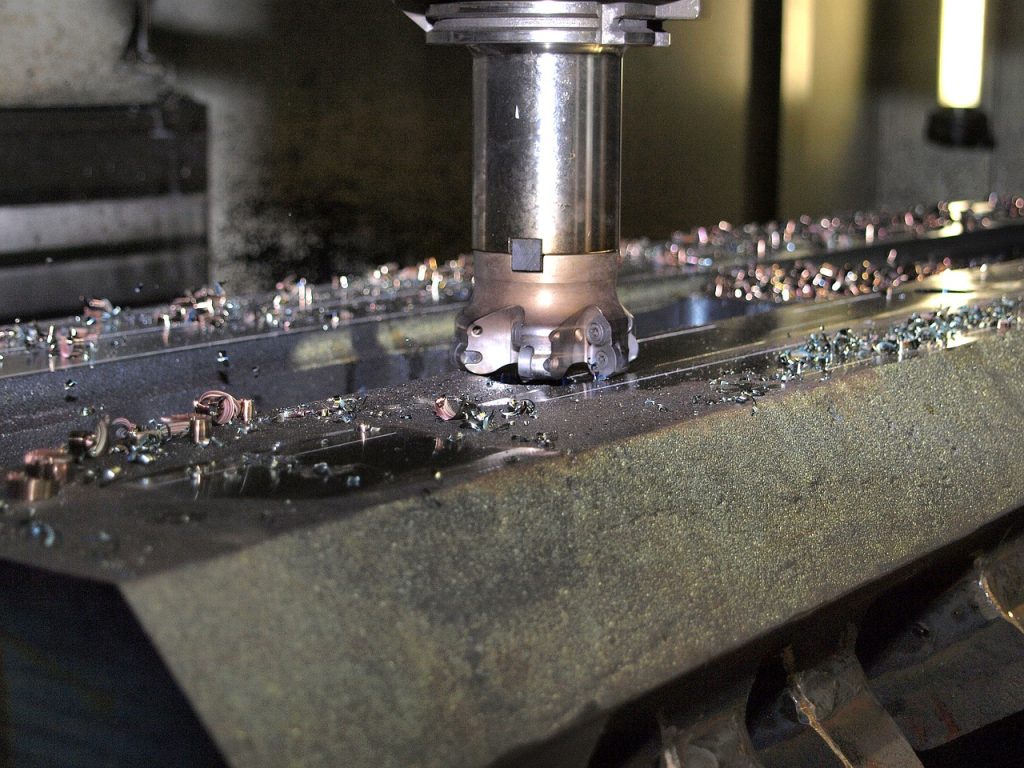

A CNC lathe is a computer-controlled machine used to shape materials, usually metal or plastic, by rotating the workpiece while cutting tools perform the shaping. These machines use pre-programmed software to automate operations that traditionally required manual effort, allowing for complex designs and intricate details to be manufactured with ease.

Key Benefits of CNC Lathe Machines

- Precision and Accuracy CNC lathes are renowned for their ability to produce parts with a high degree of accuracy, often to within thousandths of an inch. This precision is vital for industries where exact measurements are critical, such as aerospace and medical device manufacturing. CNC programming ensures consistent results, reducing the risk of human error.

- Increased Efficiency CNC lathes can operate continuously with minimal human intervention, dramatically improving production rates. Once the machine is programmed, it can run 24/7, making it ideal for high-volume production. This efficiency translates into faster turnaround times and more cost-effective manufacturing.

- Versatility CNC lathe machines can handle a wide variety of materials, including metals, plastics, and composites. They are used to create everything from simple parts to complex components with intricate details. The versatility of these machines makes them a go-to for industries with diverse production needs.

- Automation and Ease of Use One of the biggest advantages of CNC lathes is automation. The machine operates based on pre-programmed instructions, requiring minimal manual adjustments during operation. This not only saves time but also reduces labor costs, as fewer operators are needed to oversee the production process.

- Cost-Effectiveness While the initial investment in a CNC lathe can be high, the long-term cost savings are substantial. CNC machines reduce material waste, improve production speed, and require less labor, all of which contribute to lower operational costs over time. For businesses looking to scale, a CNC lathe is a smart investment.

CNC Lathe Machine Applications

CNC lathe machines are used in a wide range of industries for various applications, including:

- Automotive Parts: Precision gears, shafts, and engine components are manufactured using CNC lathes.

- Aerospace: Lightweight, durable parts like turbine blades and aircraft components rely on the precision of CNC lathes.

- Medical Devices: From surgical instruments to orthopedic implants, CNC lathes ensure the high precision required in the medical field.

- Electronics: CNC machines are used to manufacture components for electrical systems, such as connectors and housings.

How CNC Lathes Are Changing the Manufacturing Landscape

The shift toward automation in manufacturing has brought CNC lathe machines to the forefront of innovation. Traditional manual lathes required skilled machinists to operate, which not only slowed down production but also left room for inconsistencies. CNC technology has eliminated these challenges by streamlining the entire process. With the ability to replicate intricate designs and mass-produce parts with minimal variation, CNC lathes are pushing the boundaries of what’s possible in modern manufacturing.

Additionally, as industries move toward smart manufacturing and the use of advanced technologies, CNC lathes are becoming more sophisticated. Features like real-time monitoring, predictive maintenance, and integration with other automated systems are making CNC machines even more efficient and reliable.

Conclusion

CNC lathe machines are more than just tools—they’re a vital part of the modern manufacturing ecosystem. Offering precision, efficiency, and automation, these machines have become indispensable across various industries. Whether you’re looking to improve production speed, cut costs, or increase the accuracy of your parts, a CNC lathe machine is an investment that pays off in the long run. As technology continues to advance, the role of CNC lathes in manufacturing will only grow, making them an essential tool for businesses of all sizes.