Metal Lathe Machines: The Backbone of Precision Manufacturing

When it comes to metalworking, few tools are as indispensable as the metal lathe machine. Whether you’re crafting intricate aerospace components or producing everyday items, the metal lathe stands at the core of modern manufacturing, offering unparalleled precision and versatility.

What is a Metal Lathe?

At its heart, a metal lathe is a machine tool designed to shape metal by rotating the workpiece while various cutting tools are applied to it. With the ability to produce cylindrical forms with remarkable precision, often within tolerances as fine as 0.0001 inches, metal lathes are essential for industries that demand accuracy.

Types of Metal Lathes

1. Engine Lathes

- Manual operation: Engine lathes rely on skilled operators.

- Versatility: Ideal for one-off parts and custom projects.

- Applications: Commonly used for repair work and custom manufacturing.

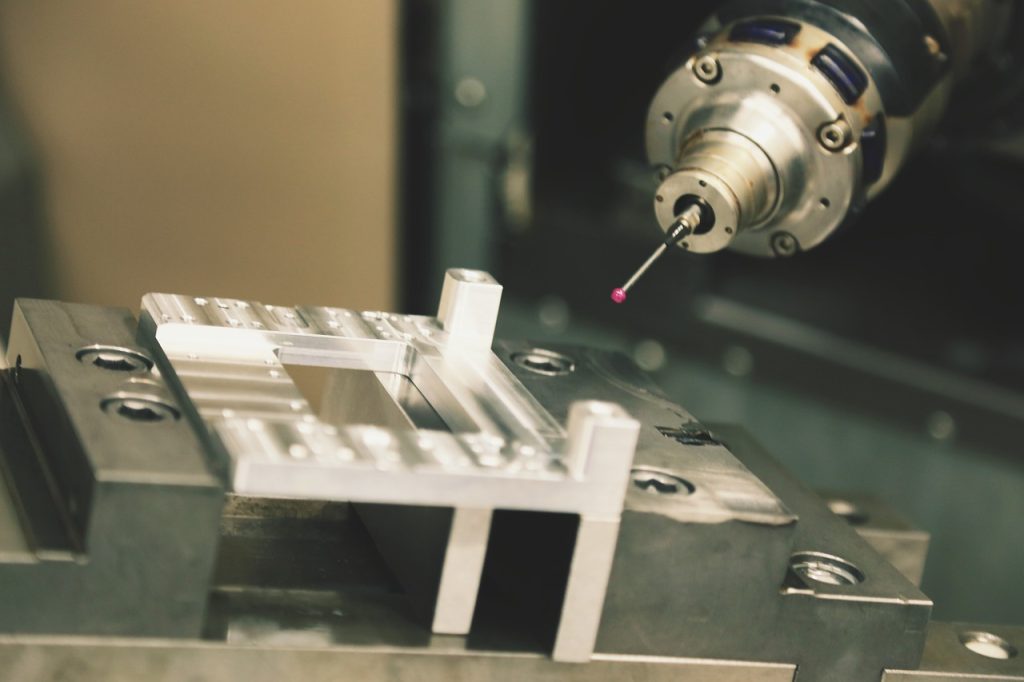

2. CNC Lathes (Computer Numerical Control)

- Automation at its finest: CNC lathes offer computerized precision for complex and repetitive tasks.

- Efficiency: Perfect for high-volume production runs with minimal operator input.

- Consistency: Delivers uniform results across multiple parts with minimal variation.

3. Toolroom Lathes

- Specialized toolmaking: Designed for high-precision work.

- Accuracy: Used in toolrooms where creating highly detailed components is critical.

- Attachments: Offers enhanced features and specialized attachments for intricate tasks.

Key Components of a Metal Lathe

Headstock

- The core of the lathe: Houses the spindle and drive system.

- Function: Responsible for rotating the workpiece at various speeds.

- Chuck: Holds the workpiece securely in place during operation.

Carriage

- Tool movement: Supports the cutting tools and controls their motion along the workpiece.

- Precision: Allows for fine adjustments to ensure accurate cutting.

Tailstock

- Stability: Provides support for longer workpieces during operations like drilling.

- Additional functionality: Used to hold tools such as dead centers for added accuracy.

Metal Lathe Operations

1. Facing

- Purpose: Creates a flat surface at the end of a workpiece.

- Critical application: Often the first step is to square off material for further machining.

2. Turning

- Function: Reduces the diameter of the workpiece, producing cylindrical forms.

- Multiple passes: Allows for deeper cuts with each pass, creating precise shapes.

3. Boring

- Internal precision: Enlarges existing holes, providing accurate internal diameters.

- Tooling requirements: Specialized boring tools are used for this operation.

4. Threading

- Versatile application: Cuts both internal and external threads for a variety of uses.

- Customization: Allows for the creation of custom thread designs for specific needs.

Critical Cutting Parameters

Speed

- Material matters: Cutting speeds are adjusted based on the material being worked on.

- Finish and tool life: Faster speeds may improve productivity but require careful management to avoid damaging tools.

Feed Rate

- Precision control: Determines how fast the tool moves along the workpiece.

- Surface quality: Higher feed rates can affect the smoothness of the surface and impact tool wear.

Common Materials for Metal Lathes

Frequently Used Metals

- Steel (various types): From mild steel to hardened alloys, steel is a primary material in lathe work.

- Aluminum: Lightweight and easy to machine, ideal for fast production cycles.

- Brass and Bronze: Known for their smooth finish, often used in decorative or electrical applications.

- Stainless Steel: Corrosion-resistant and used in high-durability parts.

- Cast Iron: Common in heavy-duty applications where rigidity is key.

Material Considerations

- Hardness and treatment: Heat-treated metals may require slower cutting speeds.

- Composition: The chemical makeup of a material impacts its machinability.

- Lubrication: The right cutting fluid is critical for heat dissipation and extending tool life.

Modern Innovations in Metal Lathes

Digital Enhancements

- Digital readouts: Modern lathes often feature DRO systems, providing real-time feedback for greater accuracy.

- Quick-change tooling: Reduces downtime by allowing faster tool swaps.

- Automated controls: Advanced features like automatic feed and spindle control streamline operations.

Precision Components

- Ball screws and linear guides: These features provide smoother motion and greater positioning accuracy.

- High-precision bearings: Ensure minimal runout, allowing for extremely accurate work on delicate projects.

Metal Lathe Maintenance

Daily Maintenance

- Cleanliness: Regularly remove chips and debris to avoid damage.

- Fluid checks: Ensure proper lubrication levels in the machine to avoid wear.

- Tool inspection: Examine cutting tools for wear or damage to maintain precision.

Preventive Maintenance

- Lubrication schedules: Follow manufacturer guidelines for proper lubrication of bearings and moving parts.

- Alignment checks: Regularly check machine alignment to ensure accuracy over time.

- Part replacement: Periodically inspect belts, gears, and other components for wear.

Safety Guidelines for Operating a Metal Lathe

Personal Protective Equipment (PPE)

- Safety glasses: Always wear eye protection to guard against flying chips.

- Proper clothing: Avoid loose clothing, which can get caught in moving parts.

- No distractions: Always focus on the task at hand when operating the machine.

Operational Safety

- Chuck key safety: Always remove the chuck key before turning the machine on.

- Emergency stops: Ensure that the lathe’s emergency stop button is always within easy reach.

- Tool setup: Securely mount tools in the tool post to avoid accidents.

Applications Across Industries

Metal lathes are vital tools across numerous industries, including:

- Aerospace: Precision machining of aircraft components.

- Automotive: Manufacturing engine parts and custom accessories.

- Medical: Producing surgical instruments and prosthetics.

- General Manufacturing: From small machine shops to large factories, lathes are used in fabricating everything from household items to industrial machinery.

Investing in a Metal Lathe: What to Consider

Key Factors

- Production needs: Higher production volumes may require CNC capabilities for efficiency.

- Space requirements: Larger lathes need more space, while mini-lathes are more compact.

- Budget: High-end lathes come with more features, but there are cost-effective options for beginners.

- Skill level: Advanced lathes require skilled operators, so training is essential.

Tips for Success in Lathe Work

- Training: Start with proper training to understand safety and operational protocols.

- Sharp tools: Always use sharp cutting tools to ensure clean cuts and avoid tool damage.

- Speeds and feeds: Adjust cutting speeds and feed rates to suit the material and project.

- Setup notes: Keep detailed notes on your setups to make repetitive tasks easier and faster.

- Preventive care: Regular maintenance will extend the life of your lathe and tools.

- Measuring tools: Invest in high-quality measuring tools to verify the precision of your work.

Conclusion

Metal lathes are an essential tool in metalworking, offering precision and versatility for a wide range of applications. From simple tasks to complex machining operations, a well-maintained lathe can deliver exceptional results for years. Whether you’re a hobbyist or a professional machinist, understanding the basics of lathe operations, materials, and maintenance will help you maximize the capabilities of your machine.

Note: Always refer to your machine’s manual for detailed operating instructions and safety procedures.