Understanding Gun Lathes: Precision Machining for Gunsmithing

Gun lathes are specialized lathes used by gunsmiths and machinists to create, repair, and customize firearm components with incredible precision. Whether crafting a new barrel or fine-tuning intricate parts, gun lathes are essential tools in the world of firearms manufacturing and modification. In this post, we’ll explore what gun lathes are, how they’re used, and why they’re a must-have for any serious gunsmith.

What is a Gun Lathe?

A gun lathe, also known as a gunsmithing lathe, is a high-precision machine tool specifically designed for working on firearm components, particularly gun barrels. These lathes are built with features that allow for the fine machining of long, narrow parts, ensuring that barrels and other gun components are manufactured or repaired to exact specifications.

Key Features of Gun Lathes:

- Long Bed Length: Gun lathes have a longer bed to accommodate the length of rifle and shotgun barrels.

- Spindle Bore Diameter: A larger spindle bore allows for the barrel to pass through the headstock, making it easier to work on long pieces.

- High Precision: These machines are designed to handle intricate work, with high levels of accuracy needed for firearms.

- Rigid Construction: The rigidity of gun lathes ensures minimal vibration during machining, which is crucial for maintaining precision.

Common Uses of Gun Lathes in Gunsmithing

Gun lathes are versatile machines used for a variety of tasks in firearm creation and repair. Some of the most common uses include:

1. Barrel Turning

One of the primary uses of a gun lathe is to turn and finish gun barrels. This involves reducing the diameter of the barrel, creating a smooth and even surface, and ensuring the barrel is perfectly straight. Precise turning is essential for maintaining the accuracy and performance of the firearm.

2. Threading

Gun lathes are used to cut threads for muzzle devices, such as suppressors or muzzle brakes. Properly threaded barrels ensure that these attachments fit securely and function correctly.

3. Chambering

Chambering is the process of cutting the chamber in which a cartridge is seated. Gun lathes are used to machine the chamber with incredible precision, ensuring the firearm operates safely and reliably.

4. Contouring

Gunsmiths use gun lathes to contour barrels, shaping them to a specific profile to reduce weight or achieve a particular aesthetic. Contoured barrels can improve the handling and balance of a firearm.

5. Bore Polishing

Gun lathes can also be used to polish the bore of a barrel, improving its performance and longevity. A smooth, polished bore reduces friction and helps prevent wear over time.

Choosing the Right Gun Lathe

When selecting a gun lathe, there are several important factors to consider to ensure it meets the needs of your gunsmithing projects:

1. Bed Length

Choose a lathe with a bed length suitable for the type of firearms you’ll be working on. Longer beds are ideal for rifle barrels, while shorter beds may suffice for handguns or smaller projects.

2. Spindle Bore Size

Ensure the spindle bore is large enough to accommodate the barrels you plan to work on. A larger spindle bore provides more flexibility when working on longer or thicker barrels.

3. Precision

Look for a lathe with high precision and minimal runout. Precision is key when working with firearms, as even the smallest errors can affect the performance and safety of the final product.

4. Rigidity and Stability

A rigid lathe minimizes vibrations and ensures smooth, consistent cuts. Stability is especially important when working on long gun barrels to prevent inaccuracies caused by flexing or movement.

Popular Gun Lathes on the Market

Several manufacturers offer gun lathes designed specifically for gunsmithing. Some of the most popular models include:

- Grizzly G0509G Gunsmithing Lathe: Known for its durability and precision, this lathe is equipped with a large spindle bore and long bed, perfect for working on rifle barrels.

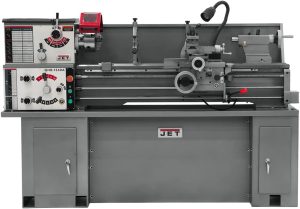

- JET GHB-1340A Gunsmith Lathe: A high-precision lathe with a sturdy build, ideal for chambering, threading, and barrel work.

- Shop Fox M1112 Gunsmith Lathe: Featuring a 2-inch spindle bore, this lathe is great for gunsmiths working on larger caliber rifles.

Why Invest in a Gun Lathe?

For professional gunsmiths, hobbyists, or firearm enthusiasts, investing in a gun lathe can be a game-changer. These machines allow for greater control and precision over your projects, helping you create custom firearms, repair components, or modify existing guns with exceptional accuracy. Whether you’re crafting a new barrel from scratch or performing intricate repairs, a gun lathe is an indispensable tool in any gunsmithing workshop.

Anatomy of a Gun Lathe

While a standard metalworking lathe shares many similarities with a gun lathe, there are several key distinguishing features:

- Precision Headstock: Gun lathes feature ultra-rigid, high-precision headstocks that can maintain concentricity and minimize run-out, essential for creating straight, uniform parts.

- Specialized Tooling: Gunsmiths require a unique set of cutting tools designed for the specific demands of firearm work, such as barrel threading, chamber forming, and contour cutting.

- Tailstock Alignment: Precise alignment between the headstock and tailstock is critical for maintaining perfect part alignment during operations like chambering and barrel work.

- Micromiter Dials: Micrometer-quality readouts on the lathe’s various slides and feeds allow for adjustments down to just a few thousandths of an inch.

- Enclosed Design: Many gun lathes feature an enclosed workspace to contain debris and provide a clean, controlled environment for sensitive firearm components.

These specialized features, combined with the skill of the gunsmith operator, allow gun lathes to achieve the level of precision necessary for creating and modifying high-performance firearms.

Gun Lathe Operations

Gunsmiths rely on their gun lathes to perform a wide range of critical tasks, including:

- Barrel Work: Turning, threading, and chambering of gun barrels to precise specifications.

- Action Modifications: Shaping, fitting, and polishing of action components like bolts, triggers, and sears.

- Parts Fabrication: Manufacturing custom replacement parts, such as sight bases, magazine wells, and other specialized features.

- Customization: Executing complex contours, profiles, and finishes on firearms for improved aesthetics and ergonomics.

By mastering the use of their gun lathe, skilled gunsmiths can not only perform expert repairs but also unleash their creativity to build truly unique, high-performance firearms.